Vehicle RESTRAINT PRODUCTS

Restraint sYSTEMS & WHEEL CHOCKS

Vehicle restraint products are designed to keep a truck or trailer stationed at the dock from moving while the trailer is being loaded or unloaded. A trailer creep occurs when the forklift moving in and out of the trailer causes the trailer to slowly move away from the dock resulting in separation from the dock leveler, the application of a vehicle restraint keeps the

Vehicle restraint products are designed to keep a truck or trailer stationed at the dock from moving while the trailer is being loaded or unloaded. A trailer creep occurs when the forklift moving in and out of the trailer causes the trailer to slowly move away from the dock resulting in separation from the dock leveler, the application of a vehicle restraint keeps the  trailer in a stationary position once it is parked in the docks. Current OSHA standards require that drivers using loading docks utilize trailer restraints at each dock. Take into consideration the volume of traffic and types of vehicles using the dock to decide if a mechanical system or wheel chocks are the best restraint option for your facility.

trailer in a stationary position once it is parked in the docks. Current OSHA standards require that drivers using loading docks utilize trailer restraints at each dock. Take into consideration the volume of traffic and types of vehicles using the dock to decide if a mechanical system or wheel chocks are the best restraint option for your facility.Restraint Systems

Automatic and Manual restraint systems are mechanical units that are mounted on the dock itself . Depending on the type of system, once the trailer is backed up into position against the dock bumpers, the system either automatically or operator engaged, securing a steel restraint arm to the horizontal RIG bar on a trailer. Systems include a full communication package that includes caution signage and light controls to signal safe loading conditions or warning the drivers when the trailer is attached to the dock. Some vehicle restraint models are available as a stand alone unit or can be integrated with other loading dock equipment.

Stop-Titeâ„¢ Series

Stop-Titeâ„¢ Series

Manual Vehicle Restraint

Recommended for lighter traffic docks as a alternative to wheel chocks. This manual restraint model requires a user to release a lever with an operating bar to activate the restraint once the trailer is positioned against the dock bumper. The operating bar is used again to release the restraint arm once loading/unloading is complete. Available as a stand alone unit or with manual light and automatic signal light options.

Stop-Titeâ„¢ Series

Stop-Titeâ„¢ Series Automatic Vehicle Restraint

With more automated features, the restraint arm is engaged and released by a simple push of the button. Once the trailer is positioned against the dock, the operator presses the engage button and the dual locking arm raises vertically to the RIB bar, automatically triggering the signal lights to indicate when the dock is safe for use. Ideal for medium traffic docks or facilities with multiple loading dock doors.

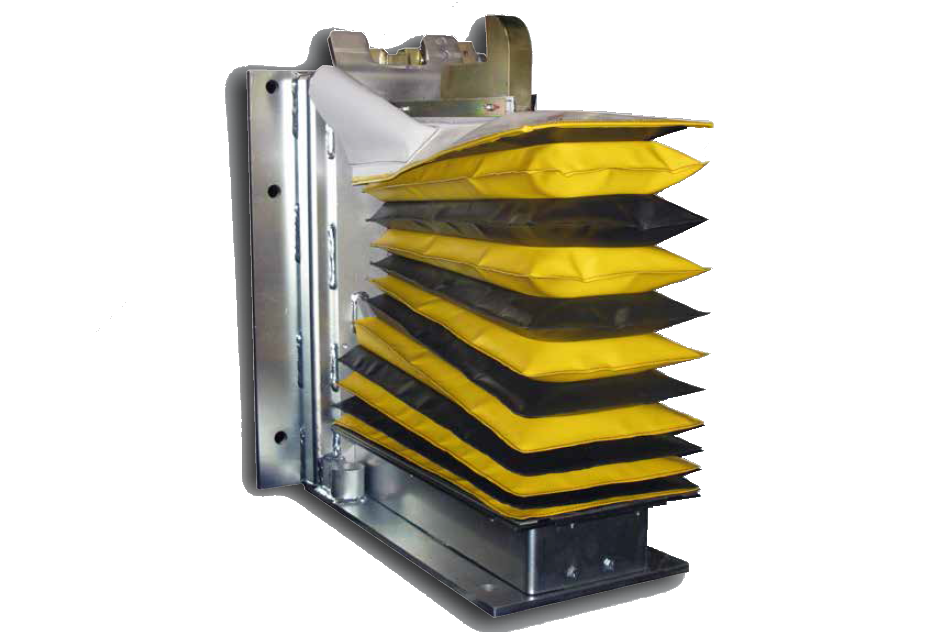

Hold-Titeâ„¢ Series

Hold-Titeâ„¢ SeriesAutomatic Vehicle Restraint

The Hold-Titeâ„¢ Restraint system uses positive hydraulic retention of the RIG bar for zero running room to minimize trailer creep. It features simple push-button operation to engage and release the trailer positioned at the dock. Full light signals automatically communicated to the interior & exterior when it is safe for the truck to leave the dock. Commonly used in facilities with higher truck traffic and or multiple docks.

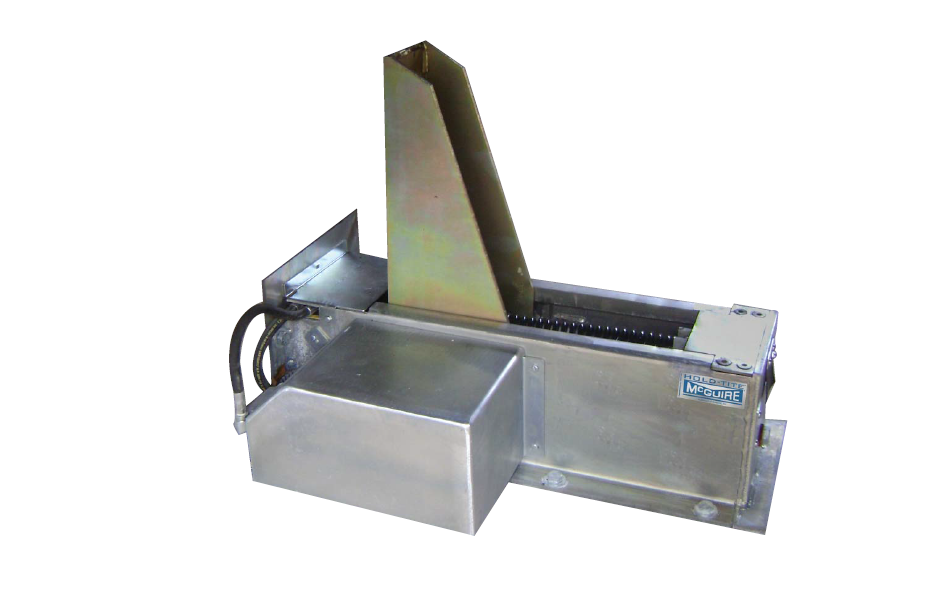

TPRâ„¢ Series

TPRâ„¢ SeriesAutomatic Vehicle Restraint

The TPRâ„¢ System features a spring loaded structural steel housing which rides down its track as a truck backs into position against the dock, allowing the RIG bar to position itself on the top of the housing. This allows the TPRâ„¢ service low profile truck carriages. The operator engages the restraint with a single push of a button and full light controls communicate to the interior and exterior the restraint's position. Ideal for high traffic distribution centers & multiple dock facilities.

Wheel chocks

Designed with curved surface contours to fit tires, wheel chocks are wedge-shaped blocks that are placed in front of the rear wheels of a trailer to prevent the trailer from moving away from the dock during loading and unloading. The type of wheel chock a facility may use depends on the surface conditions of the ground where trailers park against the dock as chocks grip to the ground’s surface, holding the wheels in place.

Most popular wheel chock styles: